CRAFTING A SWEATER

L’Envers means the opposite, the reverse in French. “Faire les choses à l’envers”: doing things the opposite way, in a different manner, offering an alternative to fast fashion. Since day 1 each piece has been knitted & sewn to order in small family workshops with great know-how in Spain, where we live. Working at a local scale makes it possible to foster strong and individual relationships with our artisans, and limit the impact we have on the environment. Let us take you through the meticulous process of knitting a L’Envers sweater.

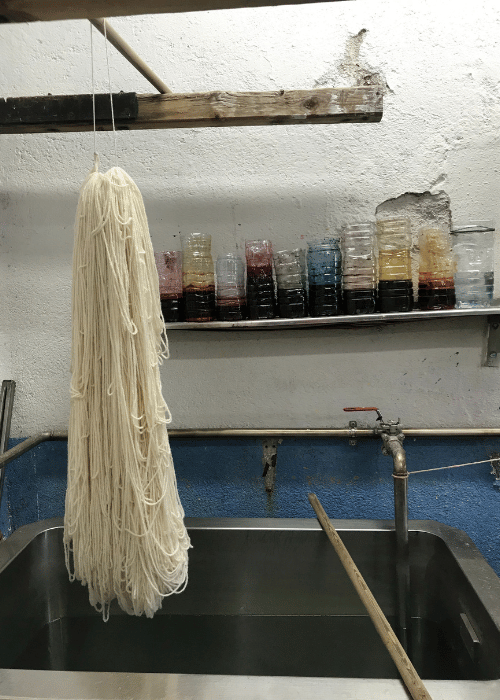

Step 1 : Dyeing the Wool Yarn

The journey begins with natural raw materials such as merino wool, yak wool, mohair wool and cotton.

These fibres are carefully selected by our spinners, who then clean, comb and spin them into high-quality yarns.

At L'Envers we have chosen to work with French, Spanish and Italian spinning mills for their know-how, the high quality of their yarns and their geographical proximity.

Once the yarn has been selected, we validate color tests, more commonly known as lab-dip, for our new collection colors before dyeing the yarn.

Once the dye baths have been completed, the yarn is finished before winding it onto a cone.

These spools of 1 or 2 kg are then sent to our knitting workshop in Béjar, near Salamanca, the last workshop still operating in this town on the old Spanish Ruta Textil (the Textile Road). Learn more about our artisans here.

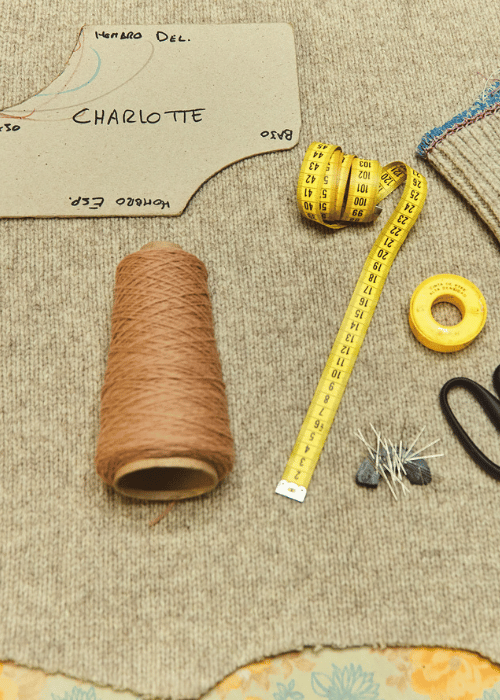

Step 2: Design development and programming the Flat Knitting Machine

Alongside the sourcing and selection of yarns, Julie and her team work on the development of the collection's models.

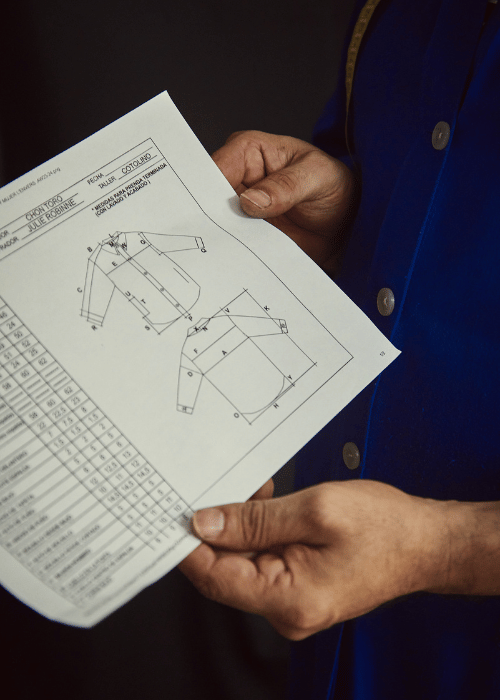

First of all, we draw up an initial technical file that includes an initial sketch, technical information and dimensions for the first prototype.

This technical file will then enable our knitter Miguel Angel to create the knitting program for each model and size using software.

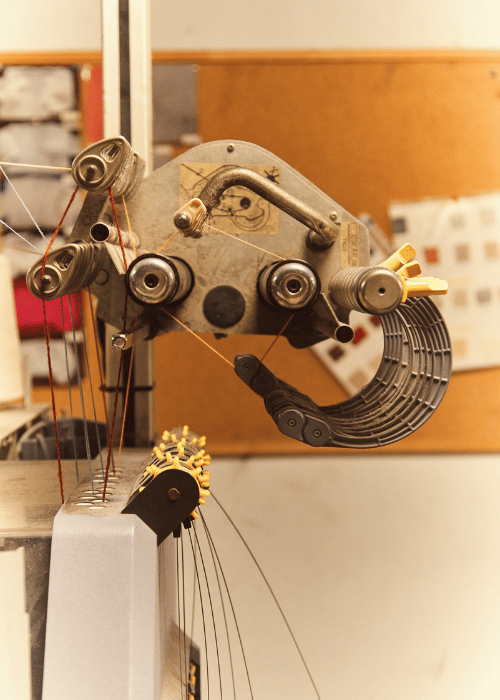

This knitting program will then enable the linear knitting machine he uses to knit the model's panels.

Before starting the knitting, Miguel Angel meticulously set up the machine, ensuring that every stitch is executed flawlessly.

Before launching a collection, we always make 2 or 3 sets of prototypes to ensure that the design, technical information, knitting program and settings are right.

Finally, once the collection has been launched and the cones of yarn received, Miguel Angel starts production one by one of each of your orders in order to offer you unique pieces made just for you.

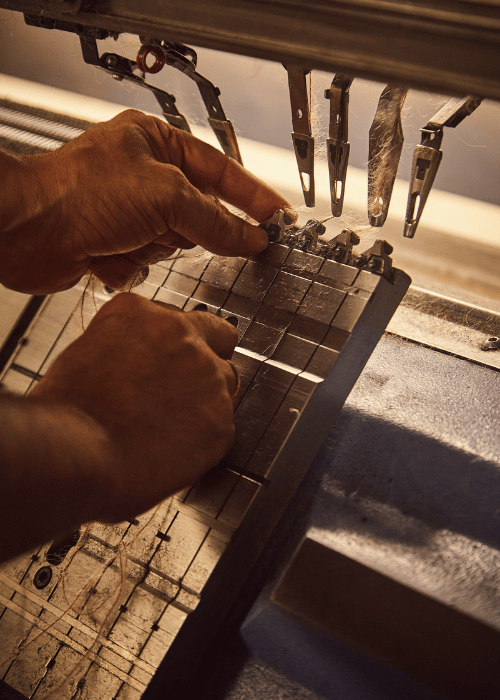

Step 3 : Knitting the Panels That Make the Sweater

With the machine programmed and ready to go, it's time to start knitting the panels that will form the body of the sweater.

Each panel is carefully monitored as it emerges from the knitting machine, with Miguel inspecting for any imperfections and making adjustments as needed.

Whether it's a classic cardigan stitch, Irish cable knit or chevron pattern, attention to detail is paramount.

Loyal to the fully fashioned methodology, each panel of the sweater is knitted individually to its applicable shape before being assembled into the finished item.

This avoids waste that typically comes from knitting generic panels that would then be cut into.

Step 4 : Washing & Stabilizing the Finished Product

Once Miguel Angel's knitted panels are finished, it's his wife Rosa's turn to wash, dry and gently steam-iron them, using techniques perfected over years of practice.

This step, also known as "blocking", is essential to stabilise the panels and impose the desired shape on the wool during knitting.

This process also smoothes the fibre, removing impurities, excess fibre and dye, and any imperfections in yarn tension.

Step 5 : Assembling the Knitted Panels

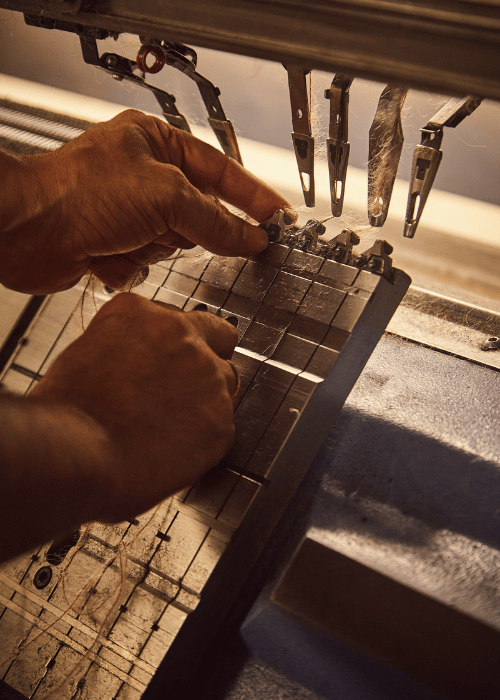

Once all the panels are knitted, washed and stabilised, it's time to assemble them into the final sweater.

This involves carefully stitching the panels together, ensuring that seams are clean and strong.

Once all the panels are assembled, it's time for the finishing touches. In Béjar, Rosa and the rest of the artisans use traditional techniques and expert machinery such as a remailleuse to bring the sweater to life.

For cardigans or other pieces with buttons, there's a final step to create the buttonhole and add the buttons.

The result is a textile item that not only looks beautiful but is also built to last.

Conclusion

Each sweater requires around 600g of wool, depending on its material, design and size, and 4 hours of work.

Each item is produced for each customer only once the order is received, making it unique while avoiding overproduction and waste.

We are profoundly proud of the garments we deliver to you and take every step possible to ensure it is knitwear that you will wear again and again and pass on.

Enjoy !

FREE SHIPPING

from 300€ to Europe, from 320€ to North America, UK, Swiss, from 360€ to Asia

FLEXIBLE EXCHANGE AND RETURNS

within 30 days

3-PART PAYMENTS

with SplitIt

CUSTOMER SERVICE

Contact Us for advice and customization